When your product can’t fail, Environmental test chambers are your best friend. They copy tough conditions—like super cold winters or hot deserts—to make sure your stuff works in the real world. Whether you’re building planes, cars, or phones, this guide tells you what you need to know about test chambers.

Environmental test chambers check how products handle different conditions. Think hot, cold, wet, shaky, or rusty stuff. They make sure your products are strong, work well, and last a long time in their real-world homes.

The big goals of Environmental test chambers are to check if products are tough, meet rules, and find weak spots. By copying real-world conditions, companies make better products. This lowers the chance of things breaking later. It’s super important for places where safety and good work are a must.

Lots of industries use Environmental test chambers. These include planes, cars, phones, army gear, green energy like solar panels, and medical tools. For example, plane parts get tested with temperature cycling test chambers to handle crazy hot and cold during flights. Car parts get shaky tests to stay safe on roads.

Environmental test chambers are special machines that copy different conditions in a safe space. They let you test stuff without putting it outside in real tough spots.

Test chambers control things like hot and cold, wet air, shakes, or rusty conditions like salt spray. For example, temperature cycling test chambers can go from cold to hot super fast, like 1°C to 15°C per minute. This shows how stuff grows or shrinks when temperatures change quick.

Environmental test chambers can make all sorts of conditions, like:

There are different test chambers for different jobs. Here are some common ones:

Climatic test chambers are super handy for testing hot, cold, and wet conditions. They’re used a lot in places like phone and car making.

LIB’s temperature humidity test chambers come in over 39 models, from 50L to 3000L. They test stuff like cold strength, hot-cold cycles, super cold storage at -70°C, and checking if things work right. They’re used to make sure products do well in all kinds of weather.

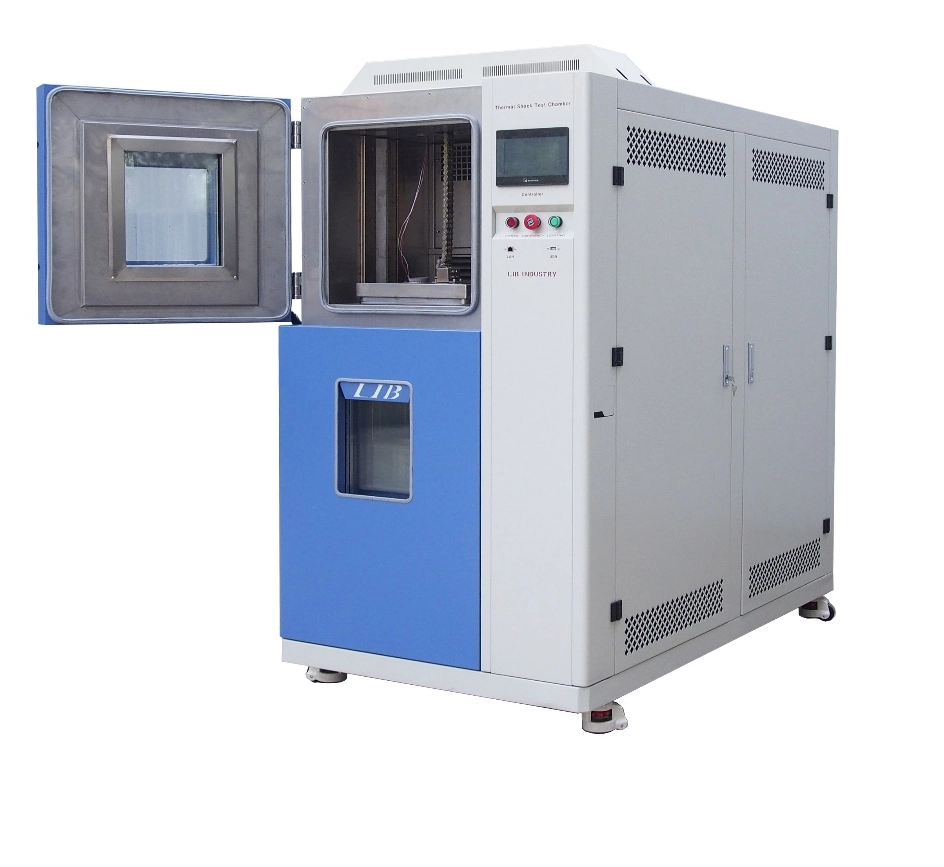

Thermal shock chambers switch fast between super hot and super cold.

LIB’s 2-zone thermal shock test chamber moves stuff between hot and cold zones automatically. This tests if things crack or get tired from quick temperature switches. It’s great for finding weak spots.

Vibration test chambers mix shaking with hot, cold, or wet tests.

These chambers find problems from shaking, like during shipping or use. For example, phone parts get shaky tests to make sure connections don’t come loose or break.

Since 2009, Xi’an LIB Environmental Simulation Industry has been a top name in making Environmental test chambers. They’re known for great quality all over the world.

LIB makes all kinds of test chambers, like benchtop chambers, cryogenic systems (-120°C), PV solar panel test chambers, and more. Their designs follow big rules like ASTM and ISO, so you know they’re good.

Picking LIB means:

Choosing the right Environmental test chamber is key to getting good test results. Here’s what to think about:

The size of your test chamber matters. You might need a small benchtop chamber or a big walk-in one. LIB’s temperature humidity test chambers go from 50L to 3000L, so you can find the right fit. For tiny spaces, benchtop chambers as small as 30L are great for phones or lab stuff.

Make sure your test chamber can handle the hot, cold, or wet you need. For example, cryogenic chambers go down to -120°C, and hot ovens reach +800°C. LIB’s temperature humidity test chambers handle wet air from 10% to 98%.

Saving energy is important, especially for long tests. Look for test chambers with energy-saving stuff like smart controls or good insulation. Also, check how easy it is to fix and clean. Chambers like LIB’s salt spray ones have automatic systems to make things easier.

Using your test chamber right helps get good results and makes it last longer.

Set up your test chamber in a spot with good air flow, away from sun or super hot or cold places. Check it often to keep it accurate. LIB’s 2-zone thermal shock test chambers have easy settings to make checking simple.

Taking care of your test chamber keeps it working well. Clean the inside often to avoid dirt messing up tests. Check parts like seals, fans, and sensors for wear. For example, salt spray test chambers need their nozzles cleaned to keep the spray even.

Environmental test chambers are super important for making sure products work in tough conditions. Think about size, hot and cold ranges, energy saving, and care needs when picking one. Setting it up right and keeping it clean makes it work even better.

Xi’an LIB Environmental Simulation Industry has been making top-notch test chambers since 2009. They offer lots of products that meet big rules like ASTM and ISO. LIB gives you trusty solutions for all your testing needs.

Q1: What Stuff Can You Test in an Environmental Chamber?

A: Environmental test chambers are super flexible. They’re used for planes, cars, phones, green energy like PV solar panel test chambers, medical tools, and coatings with salt spray test chambers.

Q2: How Long Do Tests Take?

A: It depends on the test, like temperature cycling test chambers or salt spray ones, and what your product needs. Some tests take hours. Others might take days or weeks.

Q3: Are Test Chambers Good at Saving Energy?

A: Yup! New test chambers have energy-saving stuff like smart controls, good insulation, and cool systems to save power.