If you’re running tests on automotive parts or electronic gear, you know a dust test chamber is key to checking how well they hold up in tough spots. These machines mimic sandy, dusty settings to spot weak points in seals and builds. But what good is a top-notch chamber if it breaks down mid-test? That’s where upkeep comes in. This guide dives into practical ways to keep your dust test chamber running smooth. We’ll cover daily habits, deeper checks, and why all this matters for your work and your team’s standing. Stick around – these tips could save you time and headaches.

Think about it. Your dust test chamber handles fine particles day in and day out. Dust builds up, parts wear, and without care, small issues turn big. Regular upkeep isn’t just busywork; it keeps tests reliable and gear lasting longer. Labs and shops that stay on top of this see fewer surprises, which builds trust with clients and bosses alike.

Good habits here also lift your professional game. When your equipment performs steady, your results shine, and that boosts your rep in quality control or engineering circles. Plus, it shows you’re serious about safety and standards, which matters in fields like auto or electronics where dust ingress tests are non-negotiable.

Dust chambers face constant grit. Fans spin, filters clog, and seals take a beating. Skip maintenance, and you risk early breakdowns. But with steady care, these machines can run for years without major fixes.

Start simple. Wipe down surfaces after runs to clear loose dust. This stops buildup that could jam moving parts. Check seals around doors and ports – even tiny gaps let in extra particles, throwing off tests and stressing the system. Replace worn seals quick to avoid bigger wear.

Cooling systems need love too. Compressors and fans keep temps stable during tests. Dust can coat coils, making them work harder and burn out faster. Vacuum or blow out these areas gently to keep air flowing free. It’s a small step, but it adds up to longer life for the whole unit.

Accuracy is everything in environmental testing. A dusty chamber might skew dust levels or airflow, leading to false passes or fails. That could mean shipping faulty products, hurting your brand.

Calibrate sensors often. Dust affects readings on humidity or temp gauges. Use standard tools to check and adjust – this keeps data spot-on. Also, monitor dust concentration. If blowers weaken, particles don’t spread even, messing up simulations.

Safety features tie in here. Overheat alerts or circuit breakers protect the chamber and your samples. Test these during checks to catch faults early. Reliable results build your expertise, making you the go-to person for tough tests.

Don’t wait for problems. Daily checks take minutes but pay off big. After each test, power down and inspect. Look for unusual dust piles or odd noises – these hint at issues.

Clean the interior right away. Use a soft brush or vacuum with HEPA filter to suck up residue without scratching surfaces. Avoid harsh cleaners; mild soap and water work fine on stainless steel parts. Dry everything thorough to prevent rust.

Exterior matters too. Dust off the outside to stop grime from sneaking in. Check power cords and plugs for frays – safety first.

Cleaning isn’t one-size-fits-all. Break it down by area.

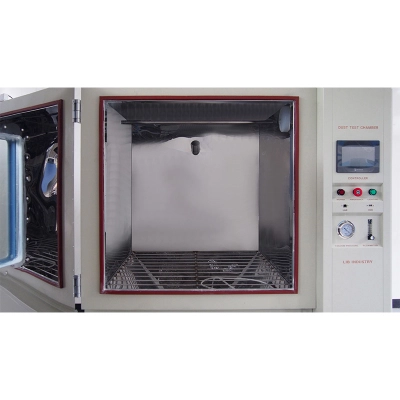

Interior Chamber: Focus on the test space. Remove samples, then vacuum floors and walls. Pay extra attention to air outlets where dust loves to hide.

Viewing Window: If your chamber has one, wipe it clear. Use a lint-free cloth to avoid streaks that block your view during runs.

Filters and Blowers: Inspect daily. Shake off loose dust, but don’t wash unless the manual says so – water can ruin some types.

A quick table for daily tasks:

| Task | Frequency | Tools Needed |

|---|---|---|

| Wipe interior surfaces | After each test | Soft cloth, mild soap |

| Vacuum dust residue | Daily | HEPA vacuum |

| Check seals and doors | Daily | Visual inspection |

This routine keeps things tidy and ready for the next job.

Step up from daily stuff. Weekly, dive deeper. Run a no-load test to see if everything cycles right – fans, temp controls, dust flow.

Monthly, tackle filters. Replace or clean them based on use. Heavy testing? Do this more often. Lubricate moving parts like fans if needed – dry bearings grind and fail.

Electrical checks fit here. Test connections for loose wires. Over time, vibrations loosen things, risking shorts.

Break it out:

Fans and blowers: Listen for rattles. Clean blades to keep airflow strong.

Sensors: Wipe dust off. Recalibrate if readings drift.

Safety systems: Simulate faults to test alarms. This ensures they kick in when needed.

Use bullet points for a monthly checklist:

Run diagnostic cycles.

Clean or swap filters.

Lubricate hinges and fans.

Log any odd readings.

These steps catch problems early, keeping your chamber dependable.

You can’t do it all alone. Bring in experts yearly for thorough inspections. They check refrigeration lines, electrical boards, and calibrate everything precise.

Look for signs like slow cooling or uneven dust spread – these scream for pro help. Servicing also updates software if your chamber has digital controls, improving efficiency.

This investment protects your setup. Well-maintained gear means consistent output, strengthening your role in the team or company. Clients notice when tests are flawless, enhancing your professional image.

Even with care, glitches happen. Here’s how to handle:

Uneven dust distribution: Clean blowers and check for blockages.

Overheating: Verify cooling system; clear vents.

Sensor errors: Recalibrate or replace.

If stuck, reach out to support. Quick fixes keep downtime low.

Go beyond basics. Track usage in a log – hours run, tests done, issues noted. This spots patterns, like when filters clog faster in humid weather.

Train your team. Everyone should know basic care to avoid mistakes. Share tips in meetings to build a culture of responsibility.

Consider upgrades. Better filters or seals can cut maintenance time. This shows forward thinking, boosting your brand as an innovative pro.

A table for performance metrics:

| Metric | Ideal Range | Action if Off |

|---|---|---|

| Dust Concentration | As per standard | Adjust blowers |

| Temperature Stability | Within 1°C | Check compressor |

| Airflow Speed | Consistent | Clean fans |

Monitoring these keeps tests top-tier.

As a trusted supplier of dust test chambers, Xi’an LIB Environmental Simulation Industry brings over a decade of experience to the table. Based in China, they craft reliable environmental test gear, including chambers that handle dust and sand simulations with ease. Their global footprint spans countries like the US, Canada, Europe, and Asia, serving big names in tech, labs, and manufacturing. With certifications like CE and ISO, they focus on quality builds and custom options. Plus, their support includes calibration, parts, and on-site help, making them a solid partner for keeping your equipment in shape.

Wrapping up, solid maintenance turns your dust test chamber into a reliable workhorse. From daily wipes to annual pros, these steps cut costs, ensure spot-on results, and lift your professional standing. Stay consistent, and you’ll see the difference in smoother operations and stronger outcomes. Ready to level up your testing game?

Key maintenance tips for dust test chambers include daily cleaning of interiors and exteriors, weekly filter checks, and monthly sensor calibrations. Always log issues to track patterns and prevent big problems.

Aim for a deep clean monthly, or more if you run heavy tests. This involves vacuuming hidden spots, wiping seals, and testing safety features to keep everything running smooth.

Calibration keeps readings accurate, which is crucial for reliable tests. Skip it, and you risk skewed data that could lead to product fails down the line.

Many daily and weekly tasks are DIY, like cleaning and basic checks. But for complex stuff like electrical inspections, call in pros to avoid risks and ensure long life.

The dust you use affects buildup. Finer particles clog faster, so adjust cleaning frequency. Always follow standards for talcum or sand to match real-world conditions without over-stressing the chamber.