Drying ovens have a key spot in lots of shops and labs. They pull out dampness from stuff like plastics, wood, or gadgets. But issues crop up now and then. This can hold up tasks or harm things. In this piece, we’ll check out usual troubles that show up. We’ll also give easy fixes for them. If you’re just starting or have lots of experience, these ideas can cut down on stress and time lost.

Drying ovens are like heated boxes that dry items. They come in various sizes for tiny tasks or large batches. Folks use them in areas like flight tech, car building, and metal shaping. The warmth draws out water or liquids from pieces, so they’re set for what comes next.

These ovens count a lot because they hurry up steps that drag on otherwise. Picture coating a piece with paint. Without good drying, the layer could blister or flake off. A solid oven holds things steady and in check. Yet, like any gear, they call for attention to run well.

You could find simple ones that reach up to certain heat levels. Others take on hotter temps. Some suit basic jobs, while others match special cases like drying without air to stop rust.

Uses differ as well. In gadgets, they dry boards for circuits. For wood, they stop bends. Plastics form without breaks. Each kind has its pluses, but snags can hit any type.

A major bother is heat that doesn’t spread right. Items in the rear may stay chilly, but those ahead get too warm. This brings bad outcomes, like spotty drying or ruined stuff.

What causes it? Often, air can’t move because of blocks. Dirt piles up on blowers or openings. Or the stuff inside packs too tight, so hot air gets stuck.

To sort it, begin with basics. Wipe the inside often. Clean racks and look for junk. Ensure things inside have gaps. Air must flow free.

If that fails, inspect the blower. Does it turn okay? A tired strap or engine might cause it. Swap out bits when needed. Plus, tune the heat gauges every couple months. Grab a temp checker to test areas in the oven.

Here’s a fast list for steady heat:

Wipe out openings and blowers from dirt.

Give space to items on holders.

Check heat in several places.

Change settings if too full.

With these moves, you can return to reliable work quick.

Steady heat leads to better stuff. In a plant, it drops bad pieces. For a little place, it grows faith with buyers. Handling this early keeps things going smooth.

Heat that bounces around is another frequent hitch. You pick 200 degrees, but it drops to 180 then jumps to 220. This throws off dry times and can wreck delicate items.

Reasons include broken controls or weak padding. Power jumps could add to it. Wires age and fail over time.

Fixes start by looking at the heat switch. If it’s old style, go to number-based for tighter hold. Pad doors and sides if warmth slips out.

Watch the power feed. Pick a steady plug or add a guard against jumps. For lasting troubles, bring in a fix person to check lines.

In one spot, a lab stopped bounces by putting in more gauges. They noted info over sessions and saw trends. Tiny changes helped a ton.

Think about a info recorder. It notes heat over periods. Find patterns and tweak. This turns hunches into real solutions.

Doors that seal loose let warmth leak. This burns extra power and drags drying. You might see cold areas or bigger costs.

Seals break down from heat and handling. Harsh stuff can wear them too.

Swap seals when they split or get stiff. It’s a fast task. Wipe the door edge before new one goes on.

Choose seals that fit your oven’s heat. Ones for high warmth last more in hot jobs.

Stop troubles by closing soft. Skip hard shuts. Clean seals after each run to clear buildup.

A tight seal holds heat in and risks out. It blocks burns from loose air. Also, it cuts run expenses.

Too much heat sets off safety stops. The oven quits in the middle, which annoys folks.

This occurs if openings clog or blowers quit. Too heavy a load can push past edges.

Clear jams first. Look at blower work. Avoid stuffing holders.

Add warnings for high heat. They alert before stop.

Routine looks stop this. Check heat parts for damage. Swap if they seem bad.

Odd sounds or shakes mean issues. Bearings could be dry, or bits loose.

Oil moving pieces as guides say. Tighten fasteners.

Set the oven on flat ground. Bumpy floors make shakes worse.

If sound stays, check the drive. It may need care.

Quiet running shows a fit machine. It also improves the work area.

Lights blink or the oven won’t kick off. Power problems scare but can get fixed.

Look at cords and plugs for harm. Try sockets.

Safety switches trip from too much. Swap with right strength.

For tough spots, call a wire expert. Skip shock risks.

Good lines keep all going.

| Problem | Likely Cause | Quick Fix |

|---|---|---|

| Uneven Heating | Blocked air flow | Clean vents, space items |

| Temperature Swings | Faulty controller | Calibrate, stabilize power |

| Door Seal Issues | Wear and tear | Replace seal, clean frame |

| Overheating | Clogged vents | Clear blockages, add alarms |

| Noise/Vibration | Loose parts | Lubricate, level surface |

| Electrical Glitches | Damaged cords | Check connections, replace fuses |

This chart offers a speedy view. Use it for checks.

Upkeep blocks troubles ahead. Clean after every use. Look over each month.

Wipe insides with light cleaner. Skip strong stuff.

Plan expert help yearly. They find hidden snags.

Solid routines stretch oven time. They also trim stops.

In active places, note upkeep. Mark what happened and when.

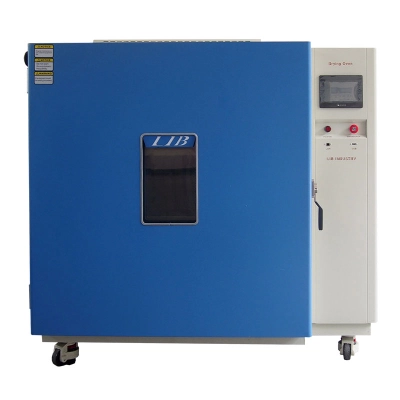

As a maker of drying ovens, Xi’an LIB Environmental Simulation Industry shines. Started in 2009, the firm began with check boxes and spread to world spots. They craft and build their own line of gear, sent to more than 40 lands. With sellers in areas like Canada, Mexico, and Italy, they give strong backing. Major groups like Intel and IBM rely on their items for top notch. They focus on pushing made-in-China tools with care for folks. If you seek trusty dry answers, give them a look.

Drying ovens help a bunch, but bumps come up. From spotty heat to loud sessions, these hitches can mess with tasks. Still, most have basic answers like wipes or switches. Keep on upkeep, and you’ll dodge large pains. This holds your work high and spending low. At last, a good oven lifts your full setup.

Folks often hit spotty heating, heat bounces, and door leaks. These come from dirt stacks or breakdown. Catch them soon to hold smooth flow.

Look at the control and power first. Tune gauges and steady current. If must, add padding for firm heat.

Too much heat stems from jammed openings or full holders. Wipe junk and cut load. Put in high-heat signals for safe.

Wipe often, check seals, and oil bits. Note looks to see trends. This stops tiny hitches from turning big.

Give space to stuff and wipe blowers. Check heat in spots. Free air move is vital for same outcomes.