In industries like electronics and automotive, products face harsh conditions daily. A temperature humidity test chamber helps simulate these to check durability. But what keeps the setup reliable? Airflow stands out as a key factor. It drives even conditions inside the chamber, cutting down on errors during tests. Without steady airflow in test chambers, results can skew, leading to costly fixes later. This post dives into why airflow matters so much for accurate environmental testing.

Air moves through a climatic test chamber to mimic real-world stresses on items like circuit boards or car parts. Steady air circulation prevents uneven spots that could ruin a test run.

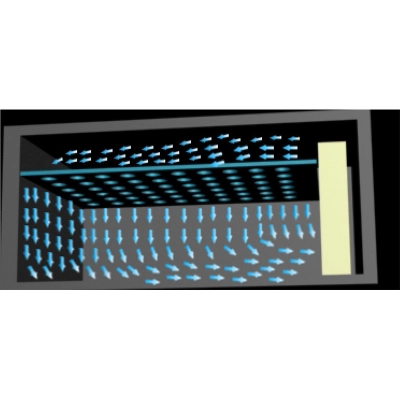

Fans and blowers push air across heaters, coolers, and humidifiers. This forced convection keeps the air mixed. For example, in a setup testing battery life under heat and moisture, air speeds around 500 to 1000 feet per minute help shift temperatures fast without lags.

Airflow ties directly to how well the chamber holds steady levels. Poor design might let air stall in corners, but good systems use baffles to guide it smoothly.

Think about a lab running cold resistance checks. If test chamber airflow dips, humidity might clump in one area, throwing off readings. Chambers often aim for a 1:3 volume ratio—test item to chamber space—to avoid blocking paths. This setup boosts temperature uniformity and cuts energy waste.

Solid airflow design for test chambers pays off in reliable data. It helps spot weak points in products early, saving time and money down the line.

Engineers rely on this for everything from solar panels to medical devices. Proper air movement ensures tests reflect actual use, building trust in the final product.

Even heat spread is vital. Forced air circulation moves warm or cool air evenly, avoiding gradients that could stress parts unevenly. In one case, a chamber with optimized fans cut temperature differences from 5°C to under 1°C across the space.

This matters for high-stakes fields like aerospace, where tiny flaws lead to big problems. Check out more on temperature humidity test chambers for setups that handle this well.

Moisture levels need to stay consistent too. Humidity control in chambers depends on air carrying vapor without pooling. Stagnant spots might dry out one side while soaking another, messing up damp heat tests.

Airflow whisks away excess moisture or adds it where needed. Labs testing fabrics or coatings see better results when air flows at steady rates, keeping relative humidity within 2-3% variance.

Accurate tests mean fewer recalls. Uniform temperature and humidity in chambers from good airflow leads to repeatable outcomes. Without it, data might show false passes or fails.

For instance, in electronics manufacturing, chambers simulate tropical conditions. Strong airflow prevents condensation buildup, which could short circuits during evaluation. This precision helps companies meet standards like IEC or UL without guesswork.

Issues crop up fast when air doesn’t move right. Hotspots form, or humidity spikes in patches. These glitches waste resources and delay launches.

Spotting them early through regular checks keeps operations smooth. Simple tweaks, like clearing vents, often fix things before they escalate.

Blocked paths create warm pockets. In a environmental test chamber, this might heat one end more, skewing thermal cycle results. Tests on automotive sensors could fail if air doesn’t reach all areas evenly.

Dust or large test items worsen this. Keeping clear zones around samples helps, as does routine cleaning to maintain flow.

Poor airflow in test chambers makes systems work harder, hiking power bills. Fans strain against resistance, leading to breakdowns.

Maintenance logs show chambers with even air last longer. Replacing filters quarterly cuts wear, ensuring steady performance over years.

| Issue | Cause | Fix |

|---|---|---|

| Uneven Temperature | Blocked vents | Clear paths, adjust fans |

| High Energy Draw | Stagnant air | Improve baffle design |

| Inaccurate Humidity | Poor circulation | Boost blower speed |

Getting airflow right starts with smart choices. Select chambers sized for your needs—too big wastes air, too small cramps it.

Regular tweaks keep things running. Labs that monitor flow weekly catch dips early.

Use plenums to direct air evenly. In walk-in models, side or ceiling vents spread it wide. Aim for speeds that match test goals—faster for quick changes, slower for steady holds.

Explore solutions tailored for climate tests to see practical setups.

Inspect fans monthly for wear. Calibrate sensors to track temperature uniformity. Upgrades like variable speed blowers adapt to different loads.

In busy facilities, this routine slashes downtime. One upgrade cut cooling times by 20% in a production line.

Pair it with controls for auto-adjusts. Humidity sensors trigger fan boosts when levels drift. This combo handles complex tests, like thermal shocks with moisture.

For more on full systems, visit the main site.

Xi’an LIB Environmental Simulation Industry serves as a key supplier in the test chamber field. Founded in 2009, this company focuses on environmental simulation equipment. It handles design, production, sales, and service under its own brand. Products reach 42 countries, backed by seven first-tier distributors worldwide. A Malaysia after-sales center supports global users. Learn more about us.

Airflow ties everything together in a temperature humidity test chamber. It drives uniform conditions, sharpens accuracy, and cuts risks. Strong designs lead to solid products that stand up to real challenges. Picking the right setup pays off in reliable results and smoother operations.

Airflow spreads heat and moisture evenly, preventing spots that skew tests. It uses fans to mix air, keeping conditions steady for accurate checks on items like electronics.

Weak flow creates hotspots or uneven humidity, leading to false data. This might pass flawed parts, causing issues later in use.

Uniform temps ensure moisture distributes right, mimicking real environments. It helps spot true weaknesses in products under stress.

It boosts efficiency, cuts energy use, and extends equipment life. Tests run faster and more reliably, aiding quick market entry.

Check vents regularly, size samples properly, and use baffles for better direction. Upgrades like speed controls adapt to varying needs.