Folks count on wearable health devices to track heart rates while they run. Or to watch sleep habits through the night. These tools range from fitness bands to sugar level checkers. They give live info that guides health choices.

But their work depends on dealing with common strains. Think sweat from exercise or a quick downpour.

Tough settings can mess up results or lead to failures. So, environmental test chambers step in here. They copy real-life situations to see if gadgets last. Labs put tools through rounds of hot, cold, and wet air. And they find weak spots soon.

Such checks keep people safe. Bad results could mean skipped warnings for odd heart beats. Good checks build faith in the gear.

Wearables face a mix of threats in use. Heat from direct sun can warp sensors. Cold snaps might drain batteries fast. Humidity often creeps in, corroding circuits.

Devices endure swings from freezing winters to scorching summers. Temperature cycling for medical wearables reveals how parts expand or contract, which could skew accuracy.

Take a heart rate monitor on a hiker. It must stay precise at 40°C peaks or -10°C lows. Testing shows if seals crack or if displays fog up.

A short bridge here: Beyond steady temps, rapid shifts pose bigger risks, leading into shock tests.

Sweat and rain test water resistance. High humidity can fog lenses or short electronics. Humidity resistance in wearable tech checks for long-term exposure effects.

In labs, chambers ramp humidity to 95% at 85°C. This mimics tropical climates or steamy bathrooms. Results guide design tweaks, like better gaskets.

Devices also deal with combined stresses. That’s why full-spectrum testing matters.

Bumps from jogging or drops during chores add wear. Chambers pair environmental factors with mechanical shakes to mimic life.

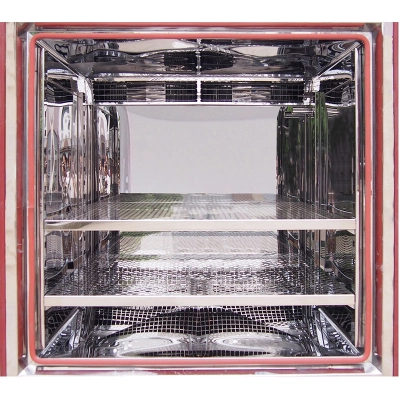

These chambers create controlled settings to mimic nature’s extremes. Air circulates evenly, heaters and coolers adjust fast, and sensors log data precisely.

From benchtop units for small batches to walk-in rooms for bulk testing, sizes vary. Configurations allow custom setups for specific needs.

Chambers handle rates up to 15°C per minute for quick changes. This speed uncovers hidden flaws.

Explore more on chamber types at the Product Center.

Different tests target specific weaknesses. Here’s a rundown.

These alternate hot and cold to stress materials. A device might cycle from -40°C to 85°C repeatedly.

This spots solder cracks or battery leaks. In one case, cycling fixed a sensor drift issue in prototypes.

Chambers hold steady high moisture levels. Tests run for days, checking corrosion or insulation breakdown.

For wearables, this ensures buttons don’t stick or screens stay clear.

Sudden shifts, like from hot to cold in seconds, simulate quick environment changes.

Baskets move samples between zones. This tests joint integrity.

A table shows common test parameters:

| Test Type | Temperature Range | Humidity Level | Duration Example |

|---|---|---|---|

| Thermal Cycling | -70°C to 150°C | N/A | 100 cycles |

| Damp Heat | 40°C | 93% RH | 21 days |

| Thermal Shock | -50°C to 100°C | N/A | 30 shifts |

These parameters draw from industry standards.

Mixing factors like heat with vibration gives fuller pictures. Wearable health device reliability testing often includes these for thorough checks.

Testing cuts failure rates. Devices last longer, reducing returns. For users, accurate data means better health insights.

In medical fields, compliance with standards like IEC ensures safety. Tested wearables withstand sweat during marathons or cold in outdoor jobs.

Labs report up to 30% improvement in durability post-testing. This boosts brand reputation.

See case studies in the Solution Center.

Developers test prototypes early. A fitness band might undergo 500 hours of humidity to check strap degradation.

In another setup, monitors face -20°C for battery life checks. Results refine designs before production.

Testing also aids certification. Regulators demand proof of resilience in varied climates.

For more on services, visit Service.

Xi’an LIB Environmental Simulation Industry shines as a test chamber seller. Started in 2009 by Yang Menglin, it began to make test boxes and sell in home lands. At the same time, it looked at world sales.

The firm is a pro spot for air copy lab gear. It has its own mark (LIB) for plan, make, sell, and fix. Now, goods go to 42 lands around the globe. There are 7 top sellers world wide and a fix spot in Malaysia to come. Spread in Canada, Mexico, Italy, Malaysia, South Korea, Bajistan, Romania. It keeps growing.

Xi’an LIB Environmental Simulation Industry has gained likes from buyers like Intel, IBM, Stanley Tools, Intertek, TUV and University of Toronto in Canada. This comes from its pro and top goods.

It looks ahead to work with you as a friend.

The firm wants to push “MADE IN CHINA” to the world with folks.

Welcome to join us!

Environmental test chambers play a key role in making wearable health devices reliable. Through targeted tests, they spot issues early, leading to tougher, more accurate gadgets. This process supports safer health tracking for everyone. As tech evolves, strong testing remains vital.

By cycling through heat and cold, testing ensures sensors stay calibrated. For instance, it prevents drifts in heart rate readings under stress.

Moisture from sweat or rain can damage internals. Chambers test resistance, ensuring devices work in humid spots like gyms or tropics.

Yes, setups adjust for size and conditions. This fits various health gadgets, from small trackers to larger monitors.

Check resources on sites like LIB Test Chambers for details on chambers and applications.