Picture this: you’re in a busy lab, staring at wet samples that need to dry fast without losing quality. Or maybe you’re in a factory where paint jobs must cure evenly before shipping. Enter the drying oven. It’s a workhorse tool that removes moisture reliably. This quick guide breaks it down. We’ll cover what it is, how it runs, types to pick, real-world uses, and tips to get the most out of yours. By the end, you’ll know exactly why a solid drying oven belongs in your setup.

A drying oven is a heated chamber designed to evaporate water or solvents from materials. Think controlled heat. No flames or wild temps. Just steady warmth that pulls moisture out gently.

These ovens shine in labs and industry. They handle everything from glass slides to metal parts. Temps range from room level up to 1200°C. Sizes fit your bench or fill a workshop.

Why care? Wet materials spoil tests, slow production, or ruin finishes. A good drying oven fixes that. It saves time. Boosts accuracy. Keeps costs down.

Short story: one lab tech dried samples overnight. Results? Spot-on data the next morning. Simple. Effective.

|

Name |

Lab Oven |

|

|

Model |

O-100 |

O-500 |

|

Internal Dimension (mm) |

400*500*500 |

700*800*900 |

|

Overall Dimension (mm) |

750*880*850 |

1100*1100*1300 |

|

Interior Volume |

100L |

500L |

|

Temperature Range |

A: Ambient ~+250 ℃,B: Ambient ~+400 ℃,C: Ambient ~+900 ℃ |

|

|

Temperature Fluctuation |

± 0.5 ℃ |

|

|

Temperature Deviation |

± 2.0 ℃ |

|

|

Heating Rate |

6 ℃ / min |

|

|

Controller |

PID color LCD touch screen controller,Ethernet connection, PC Link(Option) |

|

|

Exterior Material |

Steel Plate with protective coating |

|

|

Interior Material |

SUS304 stainless steel |

|

|

Thermal Insulation |

Polyurethane foam(Refractory brick) |

|

|

Power Supply |

380V 50Hz |

|

|

Environmental Conditional |

5℃~+35 ℃ ≤85% RH |

|

Heat rises. That’s physics. A drying oven uses electric heaters to warm the air inside. Fans circulate it evenly. Moisture turns to vapor. It escapes through vents.

Start with wet items on shelves. Close the door. Set temp and time. Heat kicks in. Air moves. Dryness happens. Done.

Every drying oven has these basics:

Pro tip: Look for stainless steel insides. Rust-proof. Easy clean.

Heat-up takes minutes. Say 6°C per minute. Cool-down? Natural or forced air.

Not all drying ovens are alike. Pick by temp, size, or job.

|

Type |

Temp Range |

Best For |

|

Low-Temp |

Up to 250°C |

Labs, moisture removal, gentle drying |

|

Medium-Temp |

250–500°C |

Paint curing, plastics, inks |

|

High-Temp |

500–1200°C |

Metal annealing, aerospace tests |

Low-temp ones? Everyday heroes. High-temp? For tough jobs.

Custom builds exist too. Need odd dimensions? No problem.

Drying ovens pop up everywhere. Here’s the rundown.

One researcher? “Switched to a precise drying oven. Experiments repeatable now.”

Bullets of top uses:

Picture a car factory. Fresh paint hits the drying oven. Hours later? Flawless finish.

Batteries for EVs need dry environments. Drying ovens deliver.

Don’t skimp here. Good features last.

|

Feature |

Why It Matters |

|

PID Controller |

Steady temps. No swings. |

|

Forced Convection |

Even drying everywhere. |

|

Viewing Window |

Check progress without opening. |

Spend more upfront. Save headaches later.

Reliable drying means better output.

Teams report 30% faster workflows. That’s real gains.

Poor choice? Uneven dry. Wasted materials. Frustration.

Keep it running smooth.

Store dry. Avoid corrosives.

Safety rules:

Follow these. Get 20 years easy.

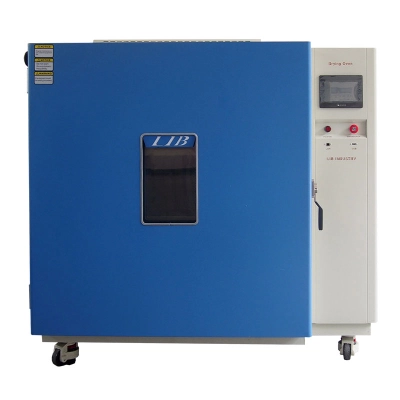

Need a dependable source? Xi’an LIB Environmental Simulation Industry stands out. Founded in 2009, they craft high-quality environmental chambers, including robust drying ovens. With over a decade in global markets, LIB serves customers across 40+ countries. Their gear meets CE, ISO, and other standards.

What sets them apart? One-stop service. From quote to install. 24/7 support. 3-year warranty. Lifelong help. Engineers train your team on-site. Spare parts ship fast worldwide.

LIB builds for the long haul. Precise. Safe. Custom if needed. Perfect partner for labs or factories.

A drying oven isn’t just equipment. It’s your edge. From precise lab work to speedy production, it delivers. Choose wisely—focus on temp control, build quality, and support. You’ll see smoother operations and stronger results.

Ready to upgrade? Explore options today. Your workflow thanks you.

A drying oven removes moisture from samples, parts, or products. Labs use it for glassware. Factories for paint curing or wood drying. Temps up to 1200°C handle it all.

Match load to volume. Benchtop for small batches. Floor models for more. Measure your trays. Add 20% space for air flow.

Yes. Models hit 500°C+. Great for aerospace or metals. Check fluctuation specs for accuracy.

Quality ones last 20 years. Regular cleaning helps. Look for strong warranties.

About 6°C per minute. From ambient to 250°C? Under an hour. Fans speed it even.