Ever wonder how stuff stays tough when temperatures swing from hot to freezing? A thermal shock test chamber puts materials through quick hot-to-cold switches to check if they can handle the stress. Find out why big industries need this super cool testing trick!

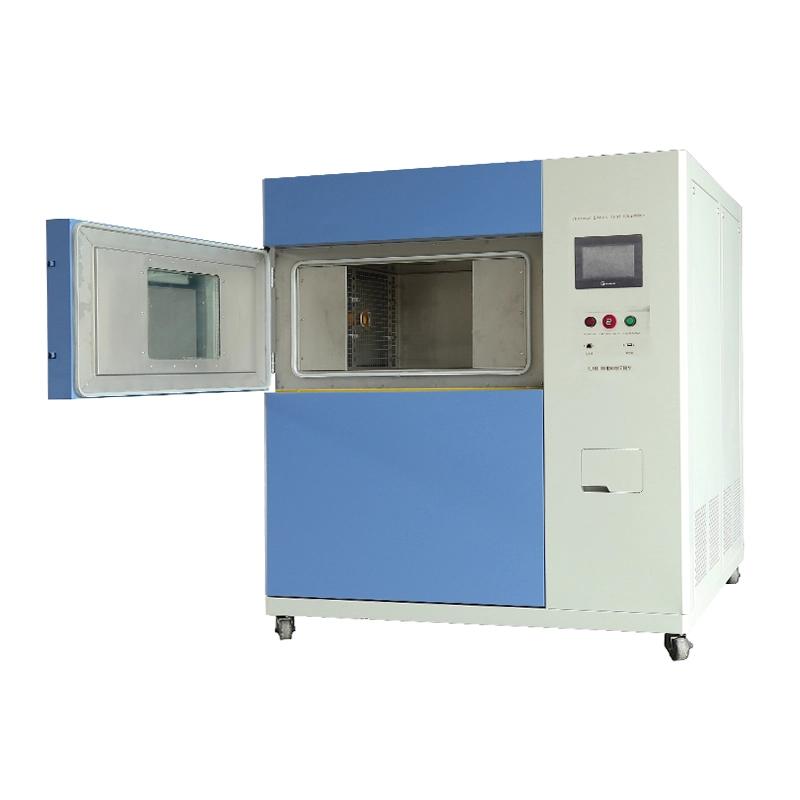

A thermal shock test chamber is a really neat machine that tests how strong stuff is when temperatures change super fast. It acts like crazy weather, going from hot to cold in a snap. This checks if things like parts or products can stay tough under stress. Thermal shock testing is a big deal for making sure products don’t break in tough real-world spots.

Thermal shock test chambers are packed with awesome stuff for exact testing. The LIB 2-Zone Thermal Shock Test Chamber moves samples from a cold box to a hot one with a basket. It’s smooth and works great. Plus, its touch-screen controller with internet hookup makes it easy to use from anywhere. The 3TS Series Thermal Shock Test Chamber is another cool one. Samples stay put while hot and cold air whooshes in through special flaps. This setup saves space and gets to test temps quick.

Here’s the deal. You put your test stuff in the chamber. It goes through hot and cold blasts back-to-back in a controlled box. There are two main kinds:

Two-Zone Chambers: Stuff moves between a hot box and a cold box.

Three-Zone Chambers: Hot and cold air flows into one box without moving the stuff. These quick switches copy real-life spots where temps jump a lot. The goal? See if the material can handle stretching, shrinking, or breaking from the heat stress.

There’s a bunch of thermal shock test chambers for different jobs:

2-Zone Chambers: Have separate hot and cold boxes with an auto-mover.

3-Zone Chambers: Use one test room with air flaps for fast results.

Cryogenic Chambers: Use super chilly cooling to hit temps as low as -120°C.

Thermal shock testing is super important for making sure stuff stays strong. It finds weak spots that could break early in tough conditions. It helps companies:

Check if designs are good.

Pick better materials.

Make things last longer. Stuff that passes these tests works great in places with wild temp swings, like planes or cars.

Lots of industries need thermal shock testing because their stuff faces rough conditions:

Electronics: Makes sure circuit boards and parts don’t mess up in hot or cold.

Automotive: Tests car parts like engines or brakes for all kinds of weather.

Aerospace: Checks plane or spaceship materials for crazy high or low temps.

Solar Energy: Tests PV Solar Panel Environmental Test Chambers to handle heat and cold cycles.

Picking a thermal shock test chamber means checking some key stuff:

Temperature Range: Make sure it hits the temps you need, like -70°C to +200°C.

Switch Time: Faster switches mean quicker tests.

Size: Pick small Benchtop Temperature Humidity Test Chambers or big floor ones based on your stuff.

Controls: Get easy touch-screen controllers you can program.

LIB has tons of options to fit what you need.

Think about these things too:

Rule Following: Make sure the chamber matches global rules like ASTM or ISO.

How Often You Test: Lots of tests need a super tough chamber.

Budget: Find a balance between cost and how good the chamber is.

Xi’an LIB Environmental Simulation Industry has been making awesome test gear since 2009. They’re pros at building thermal shock test chambers for all kinds of jobs. LIB works with big names like Intel, IBM, and Intertek, selling to 42 countries. Their stuff, like the LIB 2-Zone Thermal Shock Test Chamber, has cool controls and internet access. The 3TS Series Thermal Shock Test Chamber keeps samples still while air moves, making tests super exact.

They also make custom Cryogenic Chambers for super cold tests down to -120°C. These are great for fancy fields like aerospace or military.

LIB has a big lineup of test chambers for all sorts of needs:

Benchtop Temperature Humidity Test Chambers: Small and easy to move, great for labs testing electronics or car parts.

Fast Change Rate Thermal Cycle Test Chambers: These switch temps super fast at 5°C, 10°C, or 15°C per minute for stress tests.

Salt Spray Corrosion Test Chambers: Check how stuff holds up against rust with ASTM, ISO, and IEC rules. Sizes go from 108L to 1600L.

PV Solar Panel Environmental Test Chambers: Built to test solar panels against heat and cold swings.

Cryogenic Chambers: Use special cooling instead of liquid nitrogen for super low temps.

LIB’s stuff is tough and meets high-quality rules.

Picking the right test chamber supplier is a big deal for getting good test results. LIB stands out with years of know-how and awesome products. Their focus on new ideas and happy customers makes them a great pick for all your testing needs.

Q1: What materials can be tested in a thermal shock test chamber?

You can test all kinds of stuff! Metals, plastics, ceramics, electronics, and mixed materials go in thermal shock test chambers to see how they handle quick temp changes.

Q2: How long does a typical thermal shock test take?

It depends on what you’re testing. Most tests run from a few minutes to hours per cycle. LIB’s chambers, like the 3TS Series Thermal Shock Test Chamber, let you set custom times.

Q3: Are thermal shock test chambers energy-efficient?

Yup! Modern ones like LIB’s 3TS Series Thermal Shock Test Chamber save power by using smart air-moving systems for fast, green results.